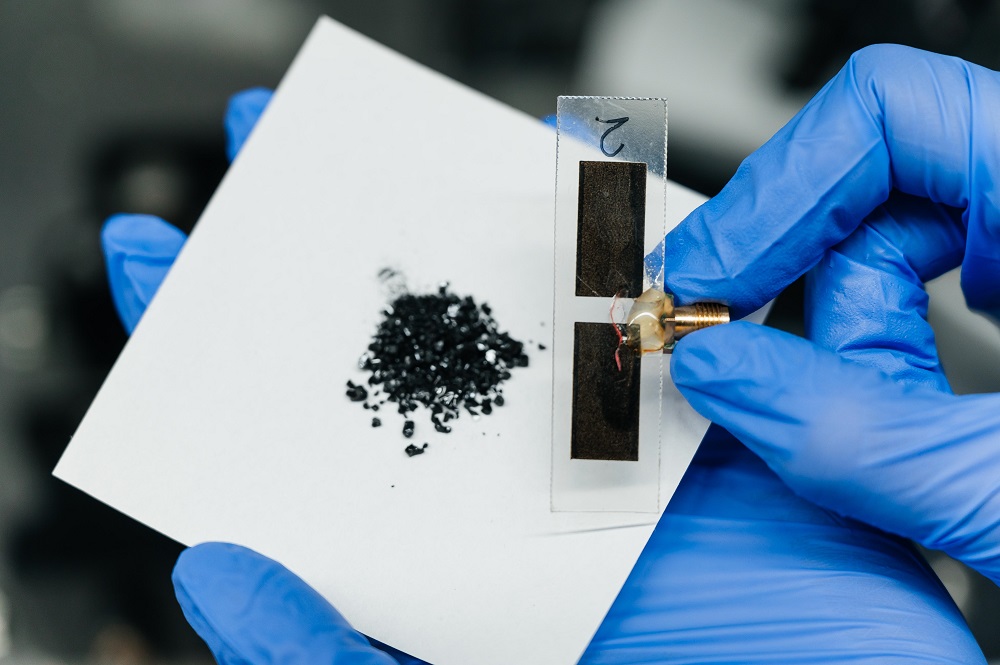

TPU scientists have created a promising composite for flexible electronics from oil waste

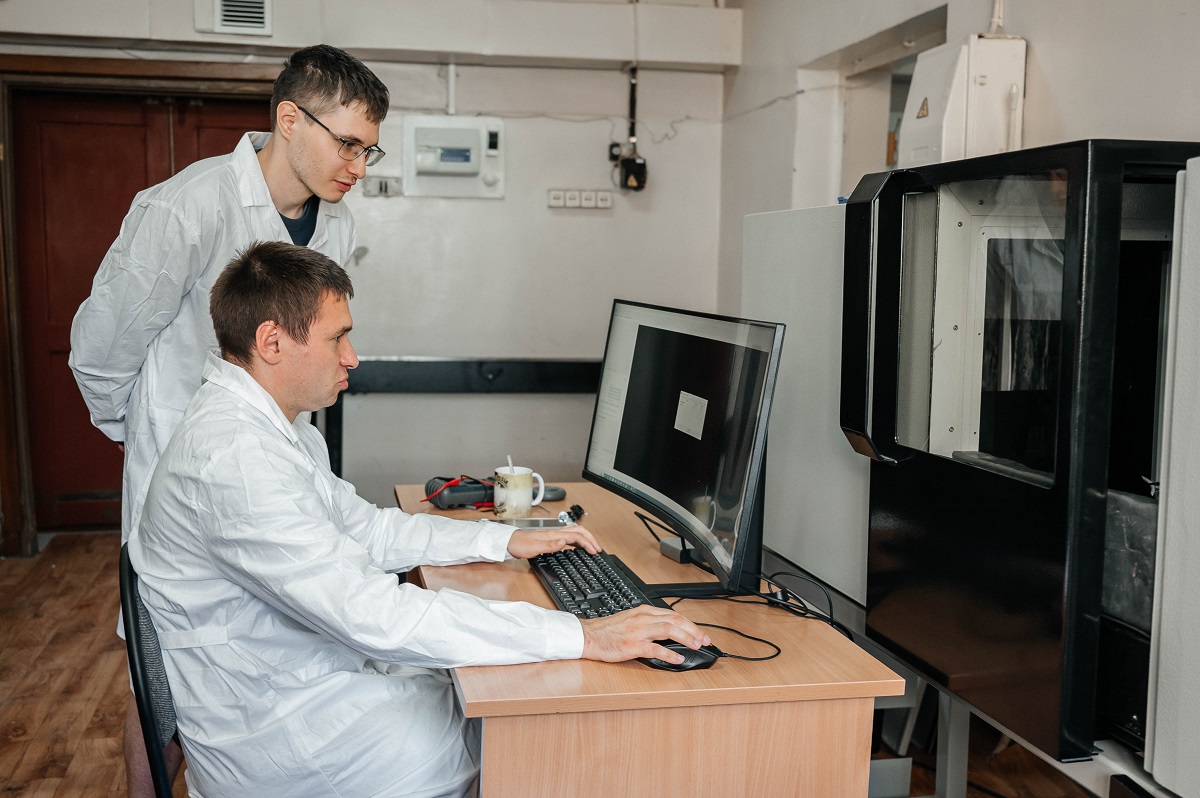

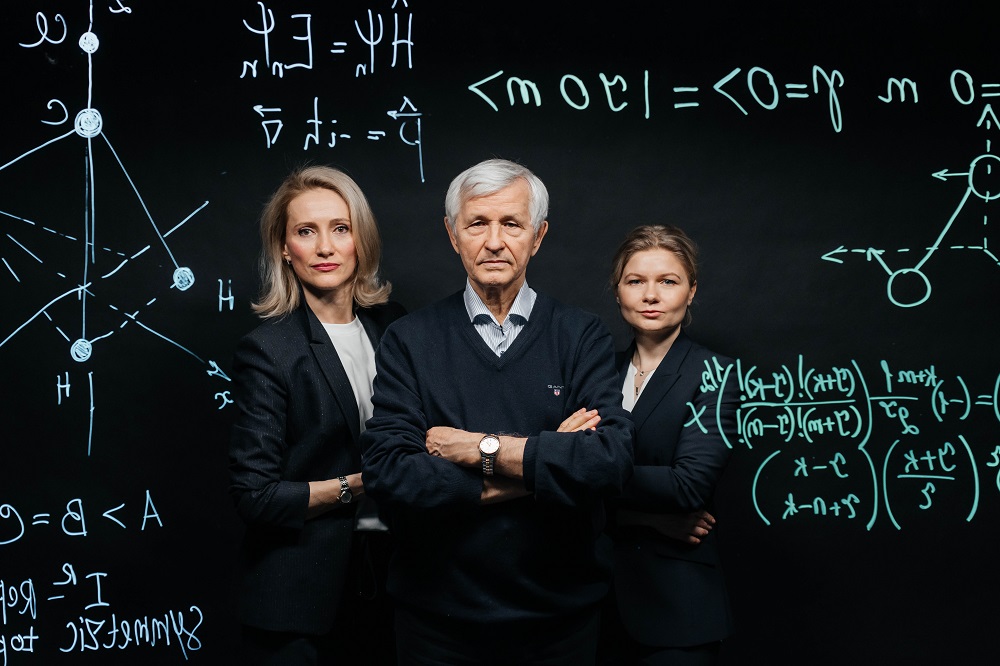

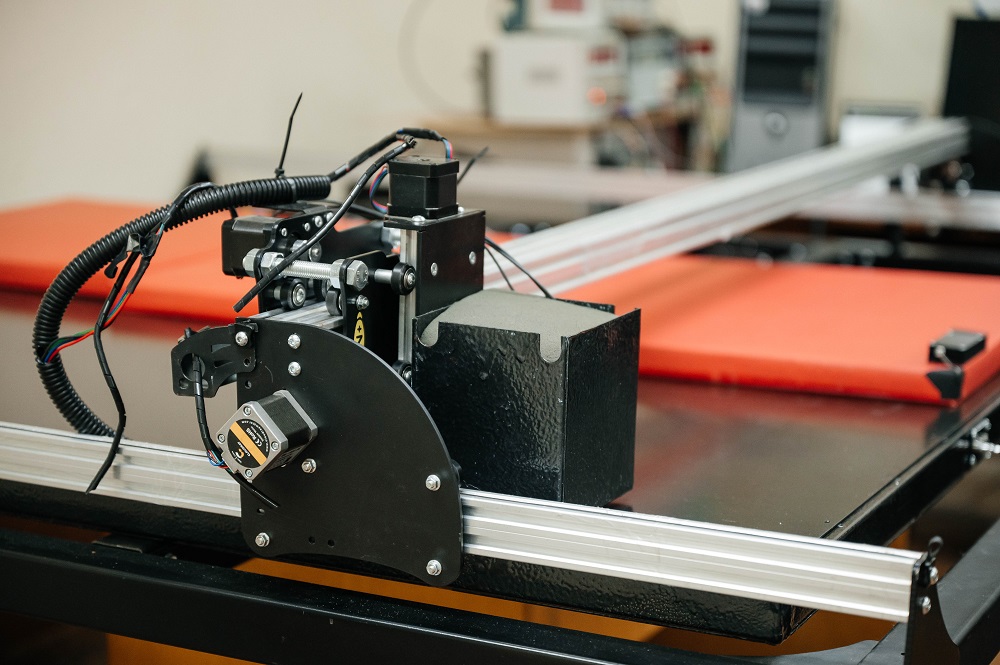

Scientists of the TPU Research School of Chemistry & Applied Biomedical Sciences have synthesized a carbon-polymer composite based on asphaltenes - by-products of oil refining. The new material has high electrical conductivity, which makes it promising for use in flexible electronics. The technology used to produce the composite is based on the method of laser processing of precursor components. It is energy efficient, simple to perform and easy to scale up. The study of laser processing mechanisms was supported by the Priority 2030 Federal Program of the Ministry of Education and Science.