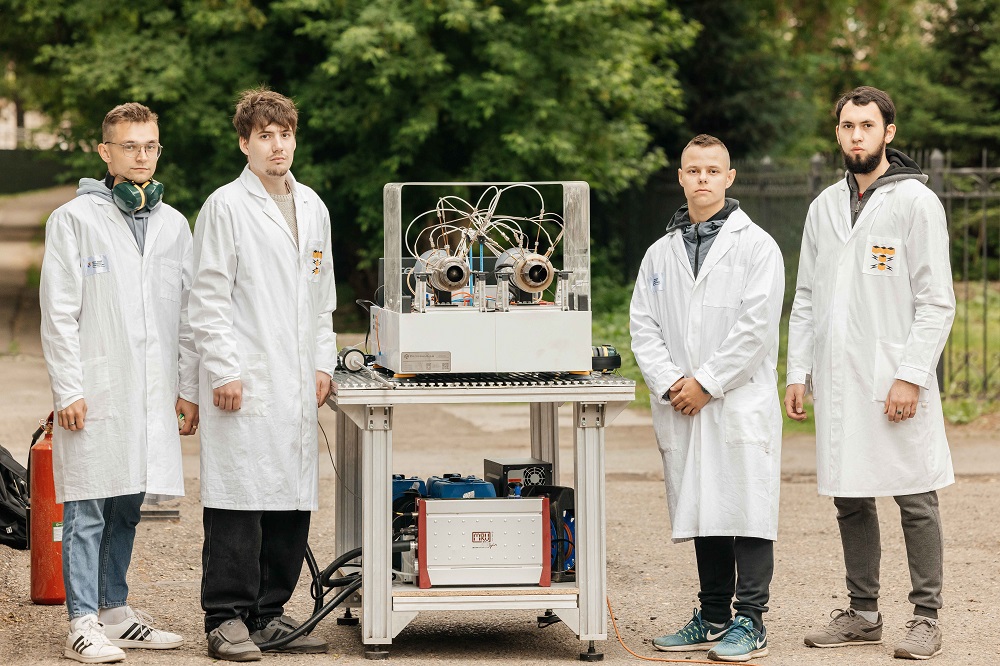

The laboratory stand consists of two gas turbine engines of different thrust range capable of carrying loads up to 18 and 25 kilograms. The main parts of the stand are equipped with sensors to measure temperature, pressure, fluid flow, traction force, concentration of anthropogenic emissions, noise and vibration intensity. All these parameters are displayed on the mimic panel in real time mode to assess their dynamics with respect to various fuels and different operation modes.

"The use of aircraft engines for testing liquid fuels is a new domain for Tomsk Polytech. The university has never had such installations before. It is a complex and challenging task to design such stands. A research team of TPU students, undergraduates, postgraduates, young scientists, as well as experts from the Central Institute of Aviation Motors and Samara University has been jointly working on it. Now, the stand has been put into operation, and the first tests with conventional fuel, namely – kerosene TS-1, have been conducted. At the same time, together with the research group of the TPU Division for Chemical Engineering, led by Prof. Elena Ivashkina, we have proceeded to the development of eco-friendly synthetic aviation liquid (SAF) fuels. We are planning to test new fuels with the use of the test stand in different operation modes," says Pavel Strizhak, project manager, head of the Heat and Mass Transfer Laboratory at TPU.

According to the researchers, the stand can be used to test fuels that have been pre-tested in terms of physical and chemical properties and meet the standards and regulations for jet fuels produced both by modern deep oil refining and from residues and wastes of the closed-loop economy (animal fats, used cooking fats, vegetable oils, microalgae and others).

"Along with the physical and chemical properties of fuels, performance properties are also important and must meet the requirements of the test program. Our new installation with low-sized gas turbine engines allows us to analyze these properties and conduct comparative comprehensive tests of fuels based on their combustion properties. This determines a further point of growth for us. We aim to develop appropriate standards for Tomsk Polytechnic University to regulate testing of different fuel types. This will make the university one of the few providers of such services in the country," says Dmitry Antonov, project executive, research engineer at the TPU Heat and Mass Transfer Laboratory.

The researchers aim to test fuels in various operating modes of propulsion systems to find the most rational fuel compositions and conditions of their combustion. In the future, they are planning to design digital twins of propulsion systems to test new types of fuels synthesized by various entities of the country.

"TPU is fully suited to create a unique database of storage, transportation, atomization, vaporization, ignition and combustion parameters of fuels of various compositions. We are going to use neural networks to generate recommendations for selecting a particular composition of fuels, technologies for their synthesis, and modes of use to improve environmental, economic, energy, and operational efficiency," says Pavel Strizhak.