Nitride-based composite materials are widely used in electronics, construction, engineering and other industries due to a unique combination of electrical, thermal and mechanical properties. The most promising method of their synthesis is self-propagating high-temperature synthesis (SHS), i.e. combustion in the air of aluminum nanopowder mixed with metal oxides. It is both cost-effective and power and time efficient.

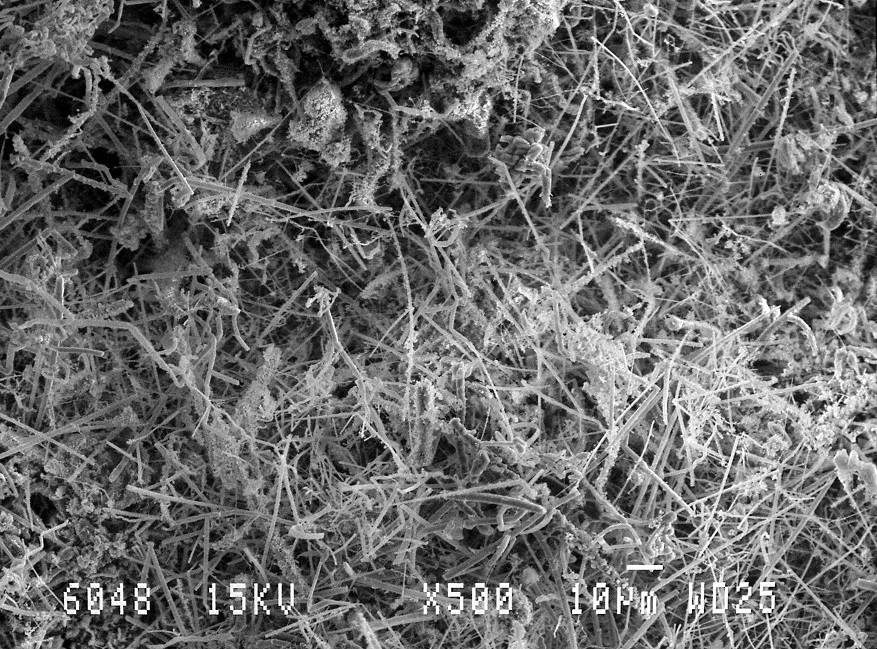

Researchers from Tomsk Polytechnic University have found a way to control the morphology of crystalline products obtained by SHS synthesis, i.e. to control their shape and structure. This was achieved by introducing special additives into the mixture. The interaction of additives and their reaction products in SHS synthesis with a magnetic field, as well as their field-assisted motion, results in crystallization of reaction products in a certain shape.

In addition, the proposed method of synthesis helps to avoid the formation of sintered reaction products that need to be additionally pulverized. It helps to obtain more loose structures, which facilitates their subsequent processing.Materials obtained using the synthesized crystalline structures are expected to have improved properties: higher thermal conductivity, wear resistance, lower flammability, and better magnetic properties. The use of such products in composites will improve the performance characteristics of existing materials,

The scientists plan to further study the products obtained by the developed technology in composite materials (ceramics, filled polymers) and abrasive materials.