The research project is supported by grant No. 23-73-00108 from the Russian Science Foundation. The research findings are published in Materials (Q2; IF: 3,748).

Phosphors are powder-like substances that convert light, mechanical, and thermal energy absorbed by them into light radiation. They are widely used in photonics, in particular, to manufacture fluorescent lamps, LEDs, emission detectors, and other devices. Russian science is currently facing a challenge to develop phosphor production technologies that could replace imported analogues. At the same time, the synthesis methods used today suffer from a number of shortcomings, such as initial and intermediate synthesis products remaining in the phosphor, heterogeneous structure of initial components.Researchers from Tomsk Polytechnic Institute have proposed a groundbreaking express method for producing yttrium-aluminum garnet doped with cerium ions, the most common luminescent ceramic used for white LEDs. Materials based on yttrium-aluminum garnet are high-tech, highly resistant to various external effects, including mechanical, thermal, chemical, and radiation.

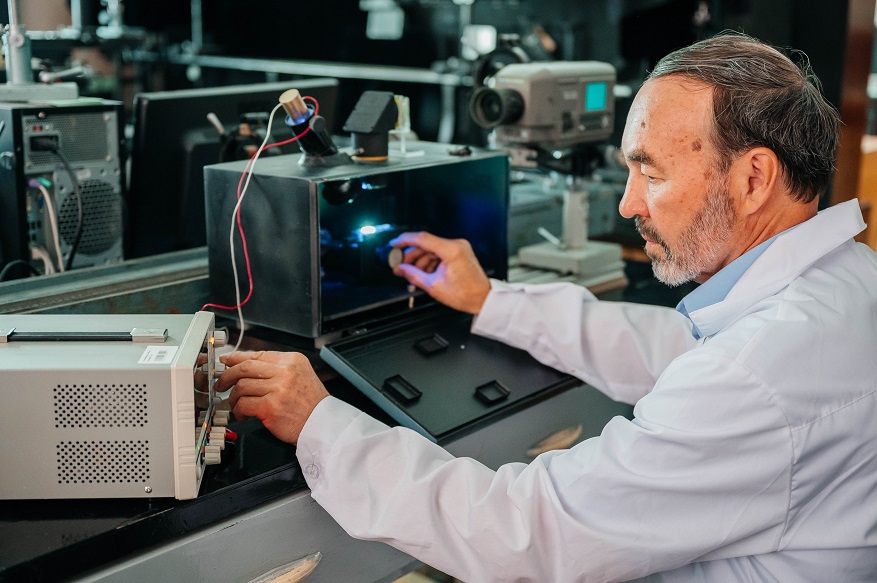

In the research, the scientists have studied the structure and luminescent properties of ceramic samples, as well as the influence of electron beam parameters and morphological composition of the components on the resulting product. It was necessary for synthesis of new types of luminescent ceramics based on the developed technological processes.The method implies using a high-energy electron beam. We synthesize the garnet from a mixture of yttrium oxide, aluminum oxide, and a cerium oxide additive in a stoichiometric ratio. This mixture is exposed to a high-power electron beam, causing radiolysis, decomposition of the oxides into ions and their subsequent fusion, thereby resulting in the synthesis of yttrium aluminum garnet. The technology makes it possible to produce 10–20 grams of the new substance per second. This is the fastest method available,

The research team has already proceeded to synthesizing complex compositions based on gallium oxide and aluminum oxide to obtain promising materials for new generation electronics.The technology helps to sinter different substances by promptly changing the components composition. It allows us to synthesize complex ceramics and find out how the content of different components affects the properties of the final product. We plan to further develop this research area in part of new effective multi-purpose technologies for radiation synthesis of materials based on refractory compounds. Now, we focus on obtaining typical conventional materials with the highest quantum and light luminescence yield controlled by spectral composition of radiation,