The scientists' findings were published in the Advanced Composites and Hybrid Materials Journal (Q1; IF:20,1).

Carbon-polymer composites are some of the most promising materials in flexible electronics. But they have limitations due to insufficient conductivity or mechanical stability. Therefore, the challenge for modern science is to obtain robust composites with improved electrical properties.

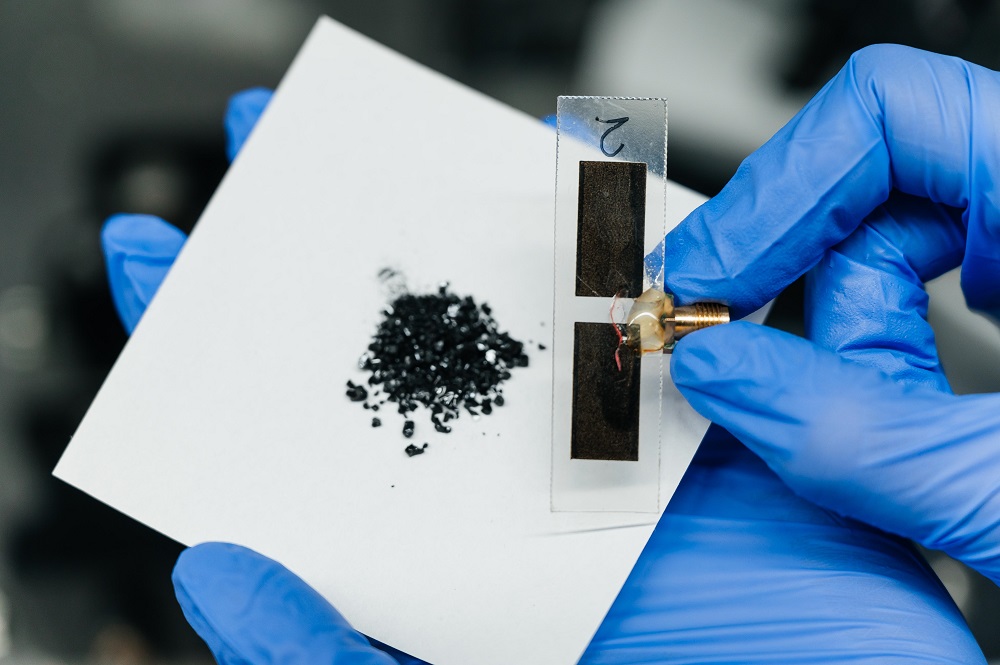

Scientists in the TERS-Team at the Research School of Chemistry & Applied Biomedical Sciences have developed an effective method for creating new composites for flexible electronics. It represents a technology for recycling heavy hydrocarbon waste. As a starting material they used asphaltenes - high molecular weight components contained in natural bitumen, fuel oils, tar and other petroleum residues. The scientists applied solutions of various asphaltenes to a substrate of polyethylene terephthalate (PET) using the drop method and then treated them with a laser.

The laser approach allows a wide range of materials to be used as substrates, including glass, polymers, metals and ceramics. Unlike thermal annealing, plasma and chemical processing, laser processing allows precise control of surface modification to create patterns of any shape. The bulk structure of the substrate material is not affected. This is important because the substrate partially determines the properties of the resulting material.РUnder the influence of laser energy, the process of dehydrogenation takes place, during which hydrogen is split off from the molecule of an organic compound. During such destruction of the CH-chain, the released carbon is used as a source for the creation of a graphite lattice, which is formed by removing oxygen-containing groups and heteroatoms from the asphaltene under the influence of the laser. This gives the formed composite improved properties,

The composite obtained by TPU researchers has low surface resistivity, homogeneity, flexibility, chemical and mechanical stability. This complex of properties expands the composite's potential application in flexible electronics. It can be used as an electrode material for strain sensors, electrothermal heaters, electrochemical sensors, supercapacitors and antennas.

"The technology for obtaining the composite based on laser processing of asphaltenes does not require high-energy processes or use of strong acids and alkalis. It is environmentally friendly, economically sound, versatile and easily scalable. This makes it an effective solution for the oil and gas industry in the recovery and recycling of heavy hydrocarbon waste into useful products," emphasizes the project leader, Raul Rodriguez, professor at the Research School of Chemistry & Applied Biomedical Sciences.